Advanced Solar Cell Manufacturing Machine: The Latest Technology in Renewable Energy

By:Admin

The Solar Cell Making Machine utilizes cutting-edge technology to automate the process of creating solar cells. This eliminates the need for manual labor, saving time and reducing production costs. The machine is capable of producing high-quality solar cells at a much faster rate than traditional methods, making it a game-changer in the solar energy industry.

This innovative technology is the brainchild of a forward-thinking solar energy company that has been a pioneer in the industry for over a decade. The company has a strong track record of developing innovative solutions for the renewable energy sector, and the Solar Cell Making Machine is just the latest example of their commitment to driving the industry forward.

The company's team of engineers and scientists have worked tirelessly to develop this cutting-edge technology, drawing on their expertise in solar energy production and manufacturing processes. The result is a state-of-the-art machine that is set to revolutionize the way solar cells are produced, making solar energy more accessible and affordable for consumers around the world.

One of the key advantages of the Solar Cell Making Machine is its ability to significantly reduce the cost of producing solar cells. By automating the manufacturing process, the machine eliminates the need for manual labor, which is one of the biggest expenses in solar cell production. This cost-saving technology has the potential to make solar energy more competitive with traditional forms of energy production, making it an attractive option for businesses and homeowners alike.

In addition to its cost-saving benefits, the Solar Cell Making Machine also offers environmental advantages. By streamlining the manufacturing process and reducing the amount of waste generated, the machine helps to minimize the environmental impact of solar cell production. This aligns with the company's commitment to sustainability and their efforts to promote clean, renewable energy sources.

The Solar Cell Making Machine has already garnered significant attention in the industry, with many experts touting it as a game-changer for the future of solar energy production. The machine's ability to increase production capacity and reduce costs is expected to have a major impact on the market, making solar energy more accessible and affordable for a wider range of consumers.

The company behind the Solar Cell Making Machine is already in talks with solar energy manufacturers around the world to implement this groundbreaking technology into their production processes. The machine has the potential to disrupt the traditional solar cell manufacturing industry, offering a more efficient and cost-effective alternative that could transform the way solar energy is produced and consumed.

As the demand for clean, renewable energy continues to grow, the Solar Cell Making Machine is poised to play a pivotal role in shaping the future of solar energy production. With its innovative technology and cost-saving benefits, the machine has the potential to make solar energy more accessible and affordable for consumers, driving the industry forward and helping to create a more sustainable future for our planet.

Company News & Blog

Cool Solutions: Maximizing the Benefits of a Cold Storage Room

As the world grows ever more connected and trade between nations booms, the importance of reliable cold storage solutions has never been greater. Luckily, {Company Name} is at the forefront of the industry, providing cutting-edge technology and unparalleled customer service to businesses around the globe.With a wide variety of cold storage options, including walk-in coolers, freezers, and refrigerated trailers, {Company Name} has something for every need. Their state-of-the-art cold rooms are a standout product, offering superior temperature control and energy efficiency to keep products fresh and safe.One of the biggest challenges facing businesses that rely on cold storage is keeping up with changing regulations. {Company Name} is always in touch with industry developments and regulatory changes, ensuring that their customers are always in compliance and able to operate smoothly.Recent additions to their offerings include high-tech monitoring and tracking systems that allow customers to manage and optimize their cold storage needs like never before. These systems provide real-time temperature readings and alerts, so businesses can quickly address any issues before they become major problems.In addition to their cutting-edge technology, {Company Name} is known for their exceptional customer service. Working with some of the biggest companies in the world, they understand the importance of timely, effective, and reliable service. With a team of highly trained technicians available around the clock, customers can count on {Company Name} to keep their cold storage running smoothly.The COVID-19 pandemic has highlighted the importance of cold storage solutions for the medical industry, and {Company Name} has risen to the challenge with their top-of-the-line vaccine storage options. With the ability to maintain ultra-cold temperatures, their cold rooms are ideal for storing sensitive medical supplies and vaccines.As the world continues to change, {Company Name} remains committed to providing the most advanced solutions and services in the industry. From small businesses to multinational corporations, their mission is to help their customers succeed by providing the best possible cold storage options. With their innovative technology and exceptional customer service, it's no surprise that they're one of the most trusted names in the industry.Whether you're looking for a small walk-in cooler or a large-scale refrigerated trailer, {Company Name} has a solution that will meet your needs. Contact them today to learn more about their products and services, and find out why so many businesses around the world trust them for their cold storage needs.

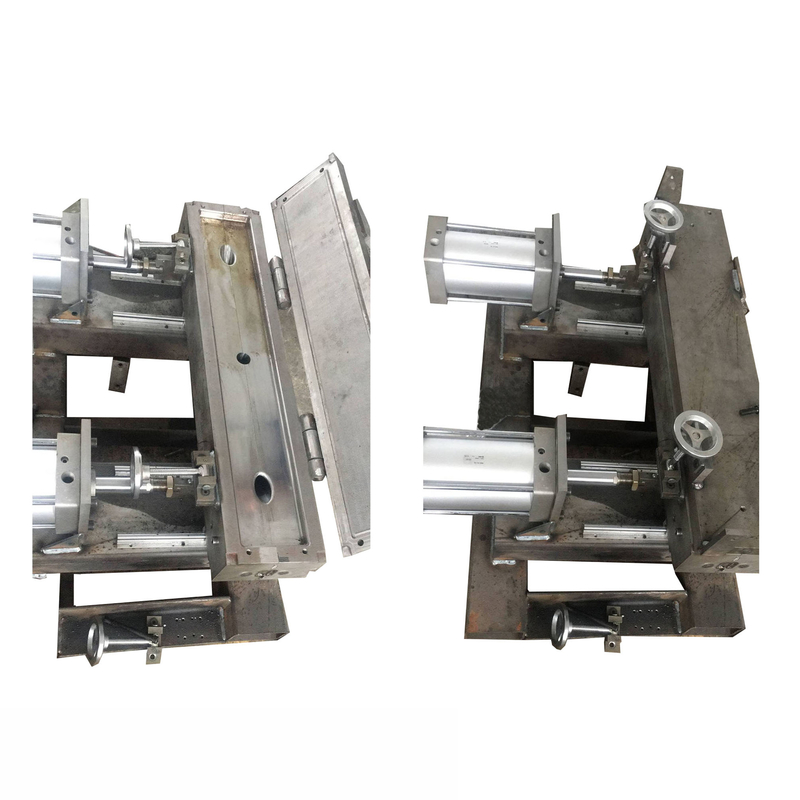

Discover the Latest Innovations in Foam Molding Machines for Enhanced Efficiency and Production

Foam Molding Machine Revolutionizes Manufacturing ProcessesIn today's fast-paced and ever-evolving world, technological advancements continue to shape various industries. Foam molding machines have emerged as a game-changing innovation, revolutionizing the manufacturing processes across multiple sectors. With remarkable efficiency and versatility, these machines have become an indispensable tool for many companies.Foam molding technology, as exemplified by the innovative machines produced by a leading company in the industry, has transformed traditional manufacturing methods. Offering advanced solutions for the production of foam products, these machines have streamlined and enhanced efficiency in numerous applications.The cutting-edge foam molding machine by the aforementioned company features state-of-the-art capabilities. It enables the production of a wide range of foam products, including packaging materials, automotive components, and even furniture upholstery. This versatility has made the foam molding machine a highly sought-after solution for manufacturers in different sectors.One of the key advantages of the foam molding machine is its ability to produce complex shapes and designs efficiently. The machine's advanced technology allows for precise and accurate molding, eliminating the need for extensive manual labor or costly tooling modifications. Manufacturers can now produce intricate foam products with ease, enabling them to meet the dynamic demands of the market effectively.In addition to its molding capabilities, the foam molding machine also offers exceptional material utilization. With its optimized design and efficient production process, manufacturers can minimize waste and maximize resource efficiency. This not only contributes to sustainable manufacturing practices but also helps reduce production costs for businesses.Furthermore, the foam molding machine ensures consistent quality in every product it produces. Its automated systems and precise controls eliminate the inconsistencies often associated with manual labor. By maintaining tight tolerances and uniformity in each foam product, manufacturers can deliver premium quality products to their customers consistently.The foam molding machine also boasts rapid production cycles, allowing manufacturers to fulfill large orders at an accelerated pace. With its high-speed capabilities, the machine significantly reduces production time and increases output. This feature is particularly beneficial for industries with tight deadlines or market demands that require quick turnarounds.Moreover, the foam molding machine contributes to a safer working environment for manufacturers. With automation reducing the need for manual intervention, the risk of injuries and accidents decreases significantly. This technology not only improves employee safety but also enhances overall productivity and efficiency.The foam molding machine's positive impact extends beyond individual manufacturers. By optimizing manufacturing processes and enabling greater efficiency, this innovative technology promotes sustainable practices and reduces environmental footprints. In an era of increasing environmental consciousness, the foam molding machine offers a viable solution to help companies improve their sustainability goals.In conclusion, the foam molding machine has ushered in a new era of manufacturing capabilities. Through its advanced technology, versatility, and efficiency, this innovative machine has revolutionized the production of foam products across multiple industries. With its ability to create complex shapes, optimize material utilization, assure consistent quality, and accelerate production cycles, the foam molding machine is becoming an essential tool for manufacturers seeking to enhance productivity and meet market demands. As the manufacturing landscape continues to evolve, this technology will undoubtedly play a pivotal role in shaping the future of various industries.

Top Quality Moulded Foam for Various Applications

Pu Moulded Foam has been making waves in the industry as a leading provider of high-quality foam products. The company has built a reputation for excellence, delivering top-notch products to a wide range of customers. With a dedication to innovation and customer satisfaction, Pu Moulded Foam has become a trusted name in the industry.The company's success can be attributed to its commitment to quality and innovation. Pu Moulded Foam utilizes state-of-the-art technology and advanced manufacturing processes to create foam products that meet the highest standards. The company's team of experienced professionals is dedicated to pushing the boundaries of what is possible, constantly striving to improve and refine their products.In addition to its commitment to quality, Pu Moulded Foam also prides itself on its dedication to customer satisfaction. The company understands that each customer has unique needs and requirements, and it works closely with them to develop customized solutions. Whether a customer needs foam products for automotive, packaging, or any other application, Pu Moulded Foam has the expertise and resources to deliver.With a focus on innovation and customer satisfaction, Pu Moulded Foam has established itself as a leader in the industry. The company's products are trusted by customers around the world, and its dedication to quality and excellence sets it apart from the competition.One of the key products offered by Pu Moulded Foam is their high-quality automotive foam. This specialized foam is used in a wide range of automotive applications, including seating, acoustics, and interior components. The company's automotive foam products are designed to meet the rigorous demands of the automotive industry, with a focus on durability, comfort, and performance.In addition to automotive foam, Pu Moulded Foam also offers a wide range of packaging foam products. From protective packaging to insulation, the company's foam products are designed to provide superior protection and cushioning for a variety of applications. With a focus on durability and performance, Pu Moulded Foam's packaging foam is trusted by customers in a wide range of industries.What sets Pu Moulded Foam apart from the competition is its commitment to innovation. The company is constantly exploring new materials and manufacturing processes to develop cutting-edge foam products that exceed customer expectations. By staying at the forefront of industry trends and technological advancements, Pu Moulded Foam continues to raise the bar for foam products.Furthermore, Pu Moulded Foam is dedicated to sustainability and environmental responsibility. The company is committed to minimizing its environmental impact by using sustainable materials and manufacturing processes. This dedication to sustainability not only benefits the environment but also ensures that Pu Moulded Foam's products are of the highest quality.Overall, Pu Moulded Foam has established itself as a leader in the industry through its commitment to quality, innovation, and customer satisfaction. With a focus on producing high-quality foam products for a wide range of applications, the company continues to set the bar for excellence in the industry. With a dedicated team, state-of-the-art technology, and a commitment to sustainability, Pu Moulded Foam is well-positioned to continue its success for years to come.

Optimizing Efficiency and Performance with Closed Cell Foam Molding Technology

[Assistant]Title: Innovations in Closed Cell Foam Molding Revolutionize Manufacturing ProcessIntroduction:Closed cell foam molding has long been recognized as a versatile material in various industries due to its exceptional properties such as insulation, strength, and lightweight nature. With the recent advancements in manufacturing technologies, combined with the expertise of {Company Name}, a leader in closed cell foam molding solutions, the industry is set to witness a transformative shift in the molding process. This article explores the cutting-edge innovations and a brief overview of {Company Name}'s contributions in revolutionizing closed cell foam molding.I. The Evolution of Closed Cell Foam Molding:Closed cell foam molding has come a long way since its inception, evolving from traditional mold-based methods to the adoption of cutting-edge technologies. Manufacturers are now leveraging advancements such as computer-aided design (CAD), simulation software, and robotics to create more precise and efficient production processes. This evolution has enabled a significant reduction in material waste, improved product quality, and faster production times.II. Introduction to {Company Name}:{Company Name}, a respected name in closed cell foam molding, has been at the forefront of these advancements, pushing boundaries and setting new industry standards. With over two decades of experience, the company prides itself on its commitment to delivering innovative solutions that cater to the unique needs of its clients. Their expertise lies in creating custom-molded foam products across a wide range of industries, including automotive, aerospace, packaging, and medical.III. Innovative Solutions:a) Advanced Mold Design: {Company Name} combines state-of-the-art molding technologies with their in-depth knowledge of materials and manufacturing processes to design molds that optimize productivity and minimize production time. Their team of experts utilizes computer-aided design tools to create intricate and precise molds, resulting in reduced material costs and improved product quality.b) Simulation and Modeling: By employing advanced simulation software, {Company Name} can accurately predict the behavior of foam during molding, offering valuable insights into flow patterns, temperature distribution, and potential defects. This allows for efficient optimization of the molding process and rapid prototyping, resulting in reduced time-to-market for clients.c) Automation and Robotics: {Company Name} understands the importance of automation in ensuring consistency and efficiency in closed cell foam molding. By implementing robotic systems and automated production lines, the company achieves higher production rates, eliminates human error, and ensures a consistently high-quality end product.IV. Industry Applications:{Company Name}'s closed cell foam molding solutions find applications in various industries:a) Automotive: Closed cell foam components play a vital role in automotive manufacturing. From impact absorption to acoustic insulation, {Company Name}'s solutions provide lightweight and durable solutions that enhance vehicle safety and comfort.b) Aerospace: The stringent requirements of the aerospace industry demand precision and reliability. {Company Name}'s expertise in closed cell foam molding enables the production of lightweight components that meet aerospace standards, while also reducing fuel consumption.c) Medical: Closed cell foam materials are essential in medical devices and equipment. With a focus on materials that are biocompatible and antimicrobial, {Company Name} ensures the production of safe and efficient medical-grade foam solutions.V. Future Outlook:The advancements in closed cell foam molding, championed by {Company Name}, are expected to shape the industry's future. The incorporation of artificial intelligence, machine learning, and further automation will lead to even more efficient processes and higher quality foam products.Conclusion:Through their innovative approach to closed cell foam molding, {Company Name} is driving a paradigm shift in the industry. Their cutting-edge solutions, advanced mold design, simulation capabilities, and automation are ushering in a new era of precision, efficiency, and product quality. By continually pushing the boundaries of technology, {Company Name} is poised to remain at the forefront of closed cell foam molding, revolutionizing manufacturing processes across various sectors.

How new tech from Shell could revolutionize pipeline inspection" could be rewritten as: "Revolutionizing Pipeline Inspection with Cutting-Edge Technology

For Immediate Release: Innovative Pipe System Proves To Be A Game Changer In The IndustryThe industrial world has just witnessed a breakthrough innovation that will revolutionize the way we look at pipe systems. The new solution, developed by a team of engineers at an industry-leading company, is poised to bring significant benefits to businesses across the globe. The cutting-edge product maximizes the reliability, performance, and flexibility of pipe systems while minimizing maintenance and downtime. This revolutionary pipe system includes a unique design that utilizes durable materials and expert configurations to maximize its longevity and strength. It is a culmination of years of research and development in response to market demands for a pipe system that can deliver improved resistance in corrosive and high-pressure applications.The advanced technology involved in creating this pipe system has provided businesses with a solution that can reliably perform in the most challenging environments. It is an ideal solution for the petrochemical, chemical, power, and process sectors. The system can handle a wide range of applications and configurations, including above and below ground installations, as well as cross-country pipelines.The benefits of this pipe system are numerous, starting with its unmatched durability and superior corrosion resistance. This product minimizes maintenance and replacement costs and ensures longer service life for end-users. The quality of its materials and precise design and engineering ensure maximum performance, reliability, and safety.Another significant advantage of this pipe system is its ease of installation. The modular approach used in its construction enables faster and easier installation, resulting in lower installation and labour costs. The system's fittings and components are flexible and adaptable, enabling businesses to customise it to meet their unique requirements.The engineers behind this product have put different rigorous tests in place, including quality and performance testing, to ensure that the product will meet the demands of the industry. The results have been overwhelmingly positive, with users claiming that the system has surpassed expectations.In summary, this pipe system is a game-changer in an industry that has been waiting for new and improved solutions. It offers significant advantages over traditional pipe systems, including superior corrosion resistance, unmatched durability, reliability, flexibility, and easy installation. This system will help businesses minimize downtime, maintenance, and replacement costs, while increasing productivity, efficiency, and profitability.To learn more about this revolutionary pipe system, visit the company’s website or contact their customer service department to schedule a consultation. This solution is poised to transform the way we look at pipe systems, providing businesses with the reliability, performance, and efficiency they require to succeed in today's competitive marketplace.

Foam Concrete Generator for Polystyrene Productions: Efficient and Energy-Saving Solution

Foam Generator Machine – Revolutionizing Construction with Foam Concrete Construction, in today's world, is as challenging and demanding as it has ever been. With the constant need to push boundaries and create structures that stand out, the industry has been innovating in various ways. One such innovation is foam concrete, which is fast becoming a popular material of choice for many. With rising concerns about environmental impact, sustainability, and energy efficiency, foam concrete offers viable solutions to some of these problems.Foam concrete is created by mixing cement, water, and foam generator products such as polystyrene foam to create a lightweight, durable and insulating material. The use of foam concrete in construction has numerous benefits. It is an excellent insulator; it has low density and offers thermal insulation, which brings energy savings. Foam concrete also has excellent soundproofing properties and is resistant to fire, water, and moisture.At Huatai Company, we are leading the way in foam concrete technology. Our HT-80S Foam Concrete Generator is a state-of-the-art machine designed to make foam concrete production efficient, environmentally friendly, and cost-effective. It is perfect for large-scale construction projects such as high-rise buildings, bridges, tunnels, and more. Our foam generator machine is easy to use, and with a compact design, it fits even in the bed of a small pickup truck.Our team of experienced engineers and technicians work tirelessly to keep our foam generator machine up-to-date with the latest technology, making it one of the most innovative machines in the market. Our expertise in designing and building ideal solutions for our clients has earned us a reputation as one of the leading manufacturers of foam concrete equipment on the market.Our range of products, including foaming agents and manufacturing equipment, is geared towards developing energy-saving construction materials. We have conducted research globally to not only develop the technology for foam concrete, but also to popularize it among contractors, architects and home builders worldwide. Our dedication to promoting eco-friendly construction materials has also helped us make a meaningful impact in the industry.At Huatai Company, our HT-80S Foam Concrete Generator Machine is designed to work in tandem with our foaming agents and polystyrene foam for efficient and quality foam concrete production. We believe in helping our customers provide the best results with the least amount of effort. Our commitment to offering state-of-the-art equipment and superior customer service is why our customers trust us.In conclusion, foam concrete is an innovative and versatile material that is revolutionizing the construction industry. Huatai Company stands at the forefront of this innovation with our state-of-the-art foam generator machine. Our machines deliver optimal results, and we provide exceptional customer service, making us the ideal partner for your foam concrete equipment needs. Contact us to learn more about our machines and how we can help you with your construction projects.

Top Foam Spray System for Effective Fire Protection

Foam Spray System, a leading provider of fire suppression solutions, has recently introduced a new and innovative product aimed at revolutionizing the way fire is fought in various industries. The newly launched system, which boasts cutting-edge technology and unparalleled efficiency, is designed to provide optimal protection and safety in the event of a fire emergency.The Foam Spray System is a state-of-the-art fire suppression solution that is suitable for a wide range of applications, including industrial, commercial, and residential settings. The system uses a specially formulated foam that is rapidly deployed to extinguish fires quickly and effectively, preventing the spread of flames and minimizing damage to property and assets.One of the key features of the Foam Spray System is its versatility and adaptability. It can be customized to meet the specific needs and requirements of different industries, making it suitable for use in a variety of environments, including manufacturing facilities, warehouses, oil and gas refineries, and more. This flexibility sets the Foam Spray System apart from traditional fire suppression methods and ensures that it can be tailored to suit the unique challenges and demands of any operation.In addition to its adaptability, the Foam Spray System is also renowned for its reliability and ease of use. The system is designed to be low maintenance, with a user-friendly interface that allows for quick and intuitive operation. This ensures that the system can be easily integrated into existing fire safety protocols, providing an added layer of protection without causing disruption to daily operations.Furthermore, the Foam Spray System is equipped with advanced monitoring and control features that allow for real-time oversight and management of fire suppression activities. This level of visibility and control gives operators the confidence and assurance that their assets and personnel are well-protected, even in the event of a fire emergency.The Foam Spray System is also environmentally friendly, employing foam that is non-toxic and biodegradable. This makes it a sustainable and responsible choice for businesses and organizations seeking to minimize their environmental impact without compromising on safety and security.The development and launch of the Foam Spray System is a testament to the commitment of the company to innovation and excellence in fire safety solutions. With a legacy of delivering high-quality products and services, the company has earned a solid reputation as a trusted and reliable partner for fire suppression needs. The introduction of the Foam Spray System further cements the company's position as a leader in the industry, offering cutting-edge solutions that set new standards for safety and performance."We are thrilled to bring the Foam Spray System to the market, as we believe it represents a significant advancement in fire suppression technology," said a spokesperson for the company. "With its unmatched versatility, efficiency, and environmental consciousness, we are confident that the Foam Spray System will meet the needs of a wide range of industries and provide unparalleled protection against fire hazards."As businesses and organizations continue to prioritize safety and risk management, the launch of the Foam Spray System comes at a crucial time. With its innovative design and advanced capabilities, the system is poised to become a go-to solution for those seeking a reliable and effective fire suppression method.In conclusion, the Foam Spray System represents a milestone in the evolution of fire suppression technology, offering a powerful and adaptable solution for a wide range of industries. With its cutting-edge features, environmental responsibility, and commitment to safety, the system is poised to make a significant impact in the field of fire safety and protection. As the company continues to lead the way in innovation and excellence, the Foam Spray System stands as a testament to its dedication to providing state-of-the-art solutions for the safety and security of businesses and communities.

Design Calculations for Indoor Seafood Processing Plant Cold Rooms: 8x10 Walk-In Cooler and Cold Storage

When it comes to processing seafood, having the right cold room design is essential to ensure that the product remains at optimal freshness and quality. In this blog, we will explore the importance of indoor seafood processing plant cold room design calculations and the benefits of using high-quality cold room equipment during seafood processing.One of the key factors in designing a cold room for seafood processing is ensuring that the temperature is maintained at a consistent level. This is important because fluctuations in temperature can cause the seafood to spoil and lose its quality. When designing a cold room, it is important to take into account the amount of seafood that will be stored and processed, as well as any additional equipment that will be required. This will help to ensure that the cold room is designed to meet the specific needs of the seafood processing plant.The 8X10 Walk in Cooler is an example of a high-quality cold room that can be used for seafood processing. This particular model features a durable construction that is designed to withstand the harsh conditions of a processing plant. It also includes advanced temperature control systems that help to maintain a consistent temperature throughout the cold room.In addition to the cold room, it is also important to consider the rest of the equipment used in the processing line. Having a complete coldroom production line that includes everything from the cold room to packaging equipment can help to streamline the processing process and ensure that the seafood remains at its peak freshness and quality.When it comes to selecting cold room equipment, it is important to choose a reliable supplier that is experienced in designing and building equipment for seafood processing plants. Guangzhou Cryo Systems Refrigeration Equipment Co., Ltd. is one such supplier that has a proven track record of delivering high-quality cold room equipment to businesses in the seafood processing industry. By partnering with a trusted supplier, businesses can set themselves up for success in the competitive world of seafood processing.In conclusion, designing a cold room for seafood processing requires careful consideration of the specific needs of the facility, including the volume of seafood being processed and any additional equipment required. By investing in high-quality cold room equipment and a complete coldroom production line, businesses can ensure that their seafood products remain at optimal freshness and quality, setting themselves up for success in the industry.

Video of Snake Stealing a Slipper Goes Viral

article on the topic.Watch: Snake Slithers Away With SlipperSnakes are one of the most fascinating creatures on earth, with their unique movements and ability to slither through tight spaces. They are also known for their predatory nature, and this video that has recently gone viral shows just how opportunistic these creatures can be. In the clip, a snake can be seen slithering away with a slipper in its mouth, leaving viewers hilariously stunned at the audacity of the creature.While this may seem like a comical story, the reality is that snakes are an important part of the ecosystem and should be treated with respect. However, incidents like this highlight the importance of being aware of your surroundings and taking precautions to prevent unwanted encounters with wildlife.At {{brand name removed}}, we are committed to providing high-quality footwear that not only looks great but also keeps your feet protected. Our slipper line is designed to be comfortable and durable, with a range of styles and colors to suit any occasion. Whether you're lounging at home or on the go, our slippers have got you covered.This video serves as a reminder of the importance of protecting ourselves and our loved ones from potential dangers. Snakes are predators, and while they may seem harmless, they can be dangerous if provoked or threatened. That's why it's important to take steps to avoid encounters with them, whether it's in your backyard or out in the wild.At {{brand name removed}}, we understand the importance of protecting our environment and its inhabitants. That's why we are committed to using sustainable practices in our manufacturing processes, to minimize our impact on the planet and preserve our natural resources for future generations.In conclusion, this viral video of a snake stealing a slipper may have generated a few laughs, but it also serves as a reminder of the importance of being aware of our surroundings and taking precautions to protect ourselves from potential dangers. At {{brand name removed}}, we are committed to providing high-quality footwear that not only looks great but also keeps you safe and protected. We believe that by working together to protect our environment and its inhabitants, we can create a brighter future for ourselves and for the planet.

Discover the Latest Trend in Resin Molds for Your DIY Projects

Title: Resin Molds Revolutionize the Crafting IndustryIntroduction:The world of crafting has witnessed a revolutionary transformation with the emergence of Resin Molds, a groundbreaking product that has taken the industry by storm. Resin Molds, manufactured by the innovative company {}, have become an indispensable tool for artists, hobbyists, and DIY enthusiasts, enabling them to unleash their creativity and produce stunning resin-based creations. With their exceptional quality, versatility, and user-friendly design, Resin Molds have become a game-changer in the crafting world.I. Overview of Resin Molds:Resin Molds are flexible, silicone-based molds that allow users to cast various shapes and designs using resin. They offer a wide range of advantages, including durability, ease of use, and the ability to capture intricate details. With these molds, individuals can create personalized jewelry, home decor, and various artistic pieces with utmost precision and professional finish.II. Unleashing Creativity:Resin Molds have opened up a world of endless possibilities for crafters and artists. With their ability to capture intricate details, these molds enable individuals to create lifelike replicas and geometric designs that were previously challenging to achieve. The molds serve as a medium for pouring resin, which, when cured, results in stunning finished products that can be celebrated as unique art pieces or cherished gifts.III. Versatility in Applications:The versatility of Resin Molds is perhaps one of their most remarkable features. They can be utilized in various crafting endeavors, such as jewelry making, resin art, candle making, soap making, and even culinary applications. These molds can be customized to fit any desired shape, size, or pattern, allowing crafters to bring their vision to life with precision and ease.IV. User-friendly Design:Resin Molds have been specifically designed to be user-friendly, making them accessible to both beginners and experienced crafters. The flexible silicone material ensures easy removal of the casted resin, preserving intricate details and preventing any damage to the mold or the finished product. Additionally, the molds are easy to clean and maintain, ensuring longevity and repeated use for countless creative projects.V. High Quality and Durability:Resin Molds, crafted by {}, boast exceptional quality and durability. The superior-grade silicone material used in their manufacturing ensures that the molds can withstand extended use without losing their shape or flexibility. This guarantees consistent, professional results and enables crafters to rely on these molds for their intricate designs time and time again.VI. Responsiveness to Market Trends:Resin Molds have experienced a surge in popularity due to the increased interest in resin crafts, as people seek unique and personalized items. Recognizing this trend, {} has continuously innovated and expanded its product line to cater to the ever-growing demand. The company has introduced a vast range of shapes, sizes, and patterns, providing crafters with unlimited options for their artistic expression.VII. Commitment to Environmental Responsibility:In line with growing environmental consciousness, {} operates with a commitment to eco-friendliness. Resin Molds are crafted using sustainable materials, and the company actively seeks ways to minimize waste and reduce its carbon footprint throughout the production process. By choosing Resin Molds, crafters can engage in their creative pursuits while contributing to a greener future.Conclusion:Resin Molds have revolutionized the crafting industry, empowering artists, hobbyists, and DIY enthusiasts to explore their creative boundaries. With their exceptional quality, versatility, and user-friendly design, Resin Molds have become an essential tool for resin crafters worldwide. As the industry continues to thrive, {} remains at the forefront of innovation, continually offering new and exciting options to inspire boundless creativity in resin crafting.